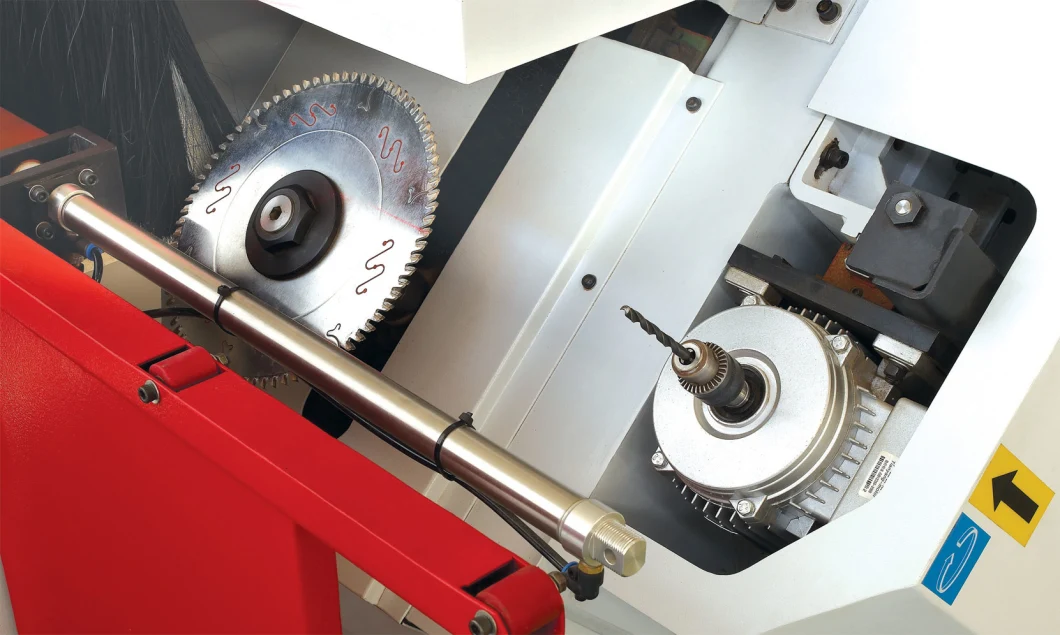

CNC Door Frame (with architrave) Cutting & Drilling & Milling Machine

CNC Door frame cutting & drilling & milling machine MDK251C/MDK252C Function:This machine is used to cut both ends of as;

Basic Info

| Control | PLC Control |

| Transport Package | Soft Package |

| Specification | 5200*2200*1900mm |

| Trademark | YUTON |

| Origin | China |

| HS Code | 8465100000 |

| Production Capacity | 50 Sets/Month |

Product Description

CNC Door frame cutting & drilling & milling machine MDK251C/MDK252CFunction:This machine is used to cut both ends of assembly door frame with L-shape architrave at 45/90 degree at the same time, it can also drill & mill connecting hole on door frame.Feature:Special clamp device, for fixing door frame with L-shape architrave.U shape direction cutting, to avoid broken edge. (One side tilting at 45 degree, the other side is vertical)

(Double side tilting at 45 degree)

Technical parameter:

| Model/ Parameter | MDK251C | MDK252C |

| Working length | 1500-3000mm(short side after cutting, min 650mm with 45° auxiliary backer for top frame-optional) | 600-2000mm (short side after cutting, max 2500mm with 90° auxiliary backer for side frame-optional) |

| Max working width | 500mm | 500mm |

| Max. Working height of L-shape architrave profile | 110mm | 110mm |

| Max. Working height of middle door frame | 50mm | 50mm |

| Overall size | 5200*2200*1900mm | 4350*2200*1750mm |

| Weight | 2050kg | 2000kg |

Main difference between MDK251C & 252C:

| Item | MDK251C | MDK252C |

| Efficiency | 130 seconds per piece (include load & unload) | 130 seconds per piece (include load & unload) |

| Process step | Cut both sides at the same time, then drill connect hole, then mill side connect slot | Cut both sides at the same time, then drill connect hole,then mill side connect slot |

| Function | Cut one side at 45°, the other side at 90°, for vertical side frame | Cut both sides at 45°, for horizontal top frame |

| Feature | 1. With better clamper than A type, which can cut door frame together with architrave which is inserted flexibly 2. Mill connect blind hole | 1. With better clamper than A type, which can cut door frame together with architrave which is inserted flexibly 2. Mill connect blind hole |

| Optional | If add one 45°backer, this model can also work for top frame.Process: cut one side of top frame at 45 degree, then turn around the door frame, so that the first side (after cutting) lean on the 45 degree backer, then cut the other side of top frame at 45 degree again.Working length after development: 650-3000mm | If add one 90°backer, and customize the max working length to be 2500mm, this model can also work for side frame.Process: cut the long frame at other machine to make one side vertical at 90 degree, then move to this machine to lean on the 90 degree backer, and cut the other side at 45 degree.Working length after development: 600-2500mm |

CNC door frame double end cutting machine MJK9045

Function: This line is used for cutting double ends of door frame at requested length, 45 degree and 90 degree can be switched automatically, manual input data or barcode scanning are both avaliable. Hardware hole & slot processing is optional.

Technical parameter:Workpiece length: 600-2400mm (min 650mm when 90 degree at both ends) Workpiece width: 90-400mm Workpiece thickness: 15-50mm Cutting motor power: 2*3kw Overall size: 6500*3020*1750mm Weight: 2000Kg

You may also like

Send inquiry

Send now